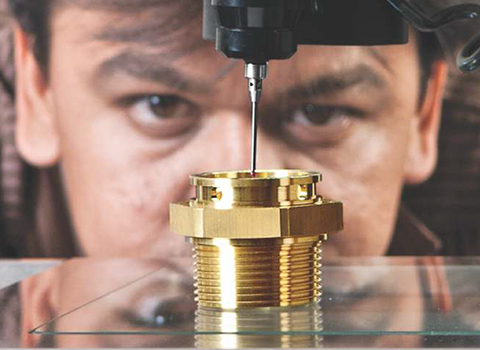

The quality Department in Brasstech is well-equipped with various sophisticated equipment including CMMs. We know that quality is not only a controlling process but also a value produced. To this end, we have quality stations all around the production area in every corner. According to our works and ISO directives, we adopt continuous improvement through studies in all processes.

Thanks to a sophisticated and rich variety of measurement devices, measurement reports and records are stored electronically ensuring full traceability. Quality is monitored at all times not only by assigned inspectors but also by all units involved throughout the whole production. In short, quality is to be produced during the production process rather than controlled.

Raw Material

Finishing

Assembly

Packaging